When it comes to a functional and visually appealing kitchen, a well-sealed worktop is a game-changer. Not only does it elevate the overall aesthetic, but it also provides crucial protection against water damage, significantly extending the life of your investment.

The key?

Silicone sealant.

In this comprehensive guide, we'll delve into the critical aspects of worktop sealing. We'll explore why it's paramount, pinpoint the specific areas that require attention, offer a detailed walkthrough on how to flawlessly seal your kitchen worktop, and shed light on the common pitfalls to avoid. With this knowledge in hand, you'll be well-equipped to achieve a professional and enduring finish for your kitchen space.

Why Seal Your Kitchen Worktop

Sealing around your kitchen worktop with silicone serves several important purposes:

Waterproofing

One of the primary reasons for sealing a kitchen worktop is to create a waterproof barrier. Kitchens are high-moisture environments, and without proper sealing, water can seep into gaps and joints, potentially causing damage over time.

Preventing Mould and Mildew

Moisture accumulation in gaps and joints can lead to the growth of mould and mildew. Silicone sealant is resistant to mould, making it an effective tool in maintaining a clean and hygienic kitchen environment.

Protecting Against Stains and Discoloration

Sealing prevents liquids, oils, and other substances from seeping into the gaps between the worktop and surrounding elements. This helps maintain the appearance of the worktop and prevents unsightly stains or discoloration.

Enhancing Durability

Properly sealed worktops are more durable and long-lasting. The sealant helps reinforce the edges and joints, reducing the risk of wear and tear over time.

Preventing Structural Damage

Water infiltration can weaken the structural integrity of the worktop and surrounding surfaces. Sealing effectively prevents this kind of damage, prolonging the lifespan of your kitchen fixtures.

Maintaining Hygiene Standards

A well-sealed worktop is easier to clean and maintain, ensuring that your kitchen remains a safe and healthy environment for food preparation.

Enhancing Aesthetic Appeal

A neatly sealed worktop creates a polished, finished look in your kitchen. It provides clean lines and a professional finish that enhances the overall visual appeal of the space.

Protecting Against Pest Infestations

Gaps around a worktop can serve as entry points for pests like ants and cockroaches. Sealing these gaps effectively denies them access, helping to keep your kitchen pest-free.

What Areas Of A Kitchen Worktop Do You Seal?

To achieve a truly effective seal, it's crucial to identify the key areas where sealing is required.

This ensures that water and moisture are kept at bay, safeguarding your kitchen worktop from potential damage. Here are the specific points you should focus on:

Sealing the Junction Between the Worktop and Wall

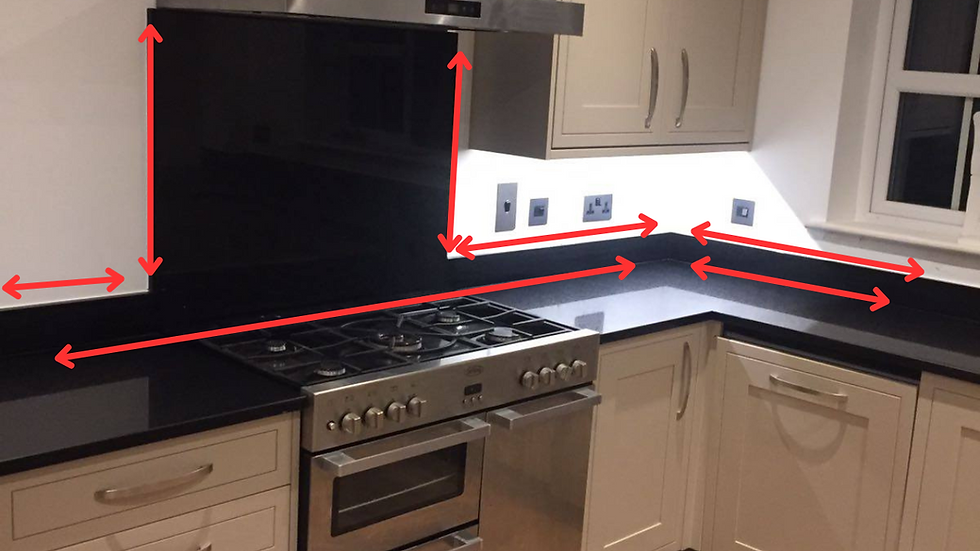

Begin by applying a bead of silicone sealant along the entire length where the worktop meets the wall. This joint is particularly vulnerable to water seepage and should be well-sealed. (See above picture).

Sealing the Corners

Pay special attention to the corners where two sections of the worktop meet. Apply sealant along the vertical joint as well as the horizontal joint to create a tight, waterproof seal.

Sealing Around Sinks and Taps

Around sinks and taps, make sure to create a complete seal. Apply sealant along the edges of the sink cut-out and around the base of the tap where it meets the worktop.

Sealing Along Edges and Joints

Inspect the edges and joints of the worktop for any gaps or seams. Apply sealant where needed to ensure there are no openings that could allow water penetration.

Sealing Any Visible Gaps

Thoroughly inspect the entire perimeter of the worktop. If you notice any visible gaps between the worktop and the surrounding elements, be sure to seal them to maintain a consistent barrier.

Sealing Around Upstands and Splashbacks

In the case of upstands or splashbacks positioned behind the hob, it's imperative to seal their perimeter as well (both where they meet the wall and worktop). This additional step ensures comprehensive protection against water intrusion in this crucial area. (See above picture).

By paying attention to these specific areas, you'll create a comprehensive and effective seal that fortifies your kitchen worktop against potential water damage.

Remember, a meticulous approach ensures long-lasting protection for your kitchen surfaces.

How To Seal Your Kitchen Worktop

Now you know the areas that need sealing. Let's take a look at exactly how to seal a kitchen worktop.

Tools and Materials Needed:

Sealant Gun:

A sealant gun, also known as a caulking gun, is an essential tool for applying silicone sealant. It allows for controlled and precise dispensing of the sealant.

Sanitary Silicone:

This is the specific type of silicone sealant designed for use in wet and humid environments, such as bathrooms and kitchens. It provides a flexible waterproof seal and is resistant to mould and mildew.

Important Note: If you are sealing a natural stone worktop such as marble, granite or even quartz. It's always best to use a neutral curing silicone. This ensures the sealant will fully adhere to the surface without damaging the stone.

Related Article 1: The Best Silicone Sealant For Showers - Ultimate Guide (this also applies for kitchens)

Related Article 2: What's The Difference Between Acetoxy & Neutral Cure Silicone Sealant

Stanley Knife or Blade:

A sharp knife or blade is necessary for cutting the nozzle of the silicone tube to the desired size. This determines the thickness of the bead of sealant.

Silicone Smoothing Tool:

This tool is used to shape and smooth the sealant after it has been applied. It helps create a clean and professional finish.

Spray Bottle of Washing-up Liquid and Water:

This mixture acts as a lubricant for smoothing the silicone sealant, preventing it from sticking to the tool or smearing along any surfaces.

Kitchen Towel or Clean/Dry Cloth:

These are used for preparing the joints and for cleaning up any spills or smudges during the application process.

Bottle of Methylated Spirit:

Methylated spirit, also known as denatured alcohol, is used for cleaning and preparing the surfaces before applying the silicone sealant.

Having these tools ready and understanding their functions will greatly facilitate the silicone application process, leading to a more successful and professional-looking finish.

Step 1) Prepare The Area

If the kitchen worktop has existing sealant already around the edge, this will need to be completely removed first before applying the new silicone.

See the following article for details on how to remove existing silicone sealant: How To Completely Remove Old Silicone Sealant - The Pro 4 Step Method

If its a newly installed kitchen, add a small amount of methylated spirit to a cloth or piece of kitchen roll, and give the joints you are sealing a wipe. Ensure the joint's are completely dirt, grit and dust free and completely dry before moving on to the next step.

Why use methylated spirit?

The methylated spirit is not only a great cleaning and degreasing solution. But the residue evaporates almost immediately. This will ensure the joints are completely dry before applying the new silicone.

2) Load The Silicone Gun

Load the silicone sealant cartridge into the gun and cut the nozzle at a 45-degree angle. The size of the opening will determine the thickness of the bead. Start with a small opening and enlarge it if needed.

3) Apply The Silicone Sealant

With the gun at a 45-degree angle, gently squeeze the trigger and move it steadily around the perimeter of the kitchen worktop. Apply a continuous bead of sealant, ensuring full coverage. Use a consistent speed to maintain an even line.

4) Smooth The Sealant

After applying the sealant, spray the bead with the soapy water, this stops the sealant from smearing or sticking to stuff it shouldn't when tooling. Then use a silicone tool to smooth and shape the bead.

This ensures an even, professional-looking finish.

DO NOT lick your finger and smooth the sealant. The bacteria in your mouth can transfer to the sealant and cause premature mould growth. Also, it's disgusting!

5) Allow Sealant To Cure

Generally, it's recommended to let the silicone dry for at least 24 to 48 hours after applying the sealant.

During this period, the sealant undergoes a process of drying and curing. This ensures that it forms a strong, watertight barrier against any movement, dirt, debris or spillages. It's important to follow the manufacturer's instructions on the specific drying and curing times for the sealant you're using, as different products may have varying requirements.

Additionally, it's advisable to avoid using the worktop during this curing period to prevent any potential disruptions or damage to the freshly applied sealant.

Related Article: How Long Does Bathroom Silicone Take To Dry (this also applies to kitchen sealant)

Comments